#industrial pumps manufacturer company

Explore tagged Tumblr posts

Text

Choosing 𝗔𝟭 𝗦𝗹𝘂𝗱𝗴𝗲 𝗗𝗲𝘄𝗮𝘁𝗲𝗿𝗶𝗻𝗴 𝗦𝗼𝗹𝘂𝘁𝗶𝗼𝗻𝘀 offers several advantages for wastewater treatment processes.

👉 𝗛𝗲𝗿𝗲 𝗮𝗿𝗲 𝘀𝗼𝗺𝗲 𝗿𝗲𝗮𝘀𝗼𝗻𝘀 𝘄𝗵𝘆 𝗔𝟭 𝗶𝘀 𝗮 𝗽𝗿𝗲𝗳𝗲𝗿𝗿𝗲𝗱 𝗰𝗵𝗼𝗶𝗰𝗲:

▪️𝐇𝐢𝐠𝐡 𝐄𝐟𝐟𝐢𝐜𝐢𝐞𝐧𝐜𝐲: A1 systems provide superior dewatering performance, reducing sludge volume effectively and quickly.

▪️𝐂𝐨𝐬𝐭-𝐄𝐟𝐟𝐞𝐜𝐭𝐢𝐯𝐞: Their systems are energy-efficient, helping to lower operational and maintenance costs in the long run.

▪️𝐃𝐮𝐫𝐚𝐛𝐥𝐞 𝐚𝐧𝐝 𝐑𝐞𝐥𝐢𝐚𝐛𝐥𝐞: A1 equipment is built with high-quality materials that ensure durability and long-lasting performance, minimizing downtime.

▪️𝐋𝐨𝐰 𝐌𝐚𝐢𝐧𝐭𝐞𝐧𝐚𝐧𝐜𝐞: The systems are designed for easy operation with minimal maintenance, reducing the need for frequent repairs or part replacements.

▪️𝐂𝐨𝐦𝐩𝐚𝐜𝐭 𝐃𝐞𝐬𝐢𝐠𝐧: A1’s equipment is space-saving, making it ideal for facilities with limited space.

▪️𝐄𝐧𝐯𝐢𝐫𝐨𝐧𝐦𝐞𝐧𝐭𝐚𝐥𝐥𝐲 𝐅𝐫𝐢𝐞𝐧𝐝𝐥𝐲: By reducing sludge volume, A1 helps lower waste disposal costs and minimizes the environmental impact of sludge handling.

▪️ 𝐂𝐮𝐬𝐭𝐨𝐦𝐢𝐳𝐚𝐛𝐥𝐞 𝐒𝐨𝐥𝐮𝐭𝐢𝐨𝐧𝐬: A1 offers flexible dewatering solutions tailored to specific industrial needs, ensuring optimal results for different sludge types.

These factors make A1 an excellent choice for efficient, cost-effective, and sustainable sludge dewatering.

☎️ 𝗠𝗼𝗿𝗲 𝗜𝗻𝗳𝗼𝗿𝗺𝗮𝘁𝗶𝗼𝗻

📱 +91 9953088849, +91 062043 85227

🌐 www.a1blowers.com

#gujarati #bengaluru #noidacity #aircompressor #DelhiNews #EFFLUENTTREATMENTPLANT #aircompressorparts #india #aircompressorservice #sewagetreatmentplant #sludge #sludgemetal #dewatring #screwpress #watertreatment #watertreatmentsolutions #watertreatmentplant #wastewater #wastewatertreatment #wastewatertreatmentplant #sewagetreatment #effluenttreatment #sewagepump #water #watersolutions #watersolution #GujaratNews #ahmedabad #vatva #gandhinagar #punjabi #haryana #ghaziabad #noidadiaries #delhi #delhincr #rajasthan #ajmer #jaipur #bhopal #industrial #industry #industrialdesign #machine #machinery #plantas #Yamunanagar #chandigarh #ludhiana #LudhianaNews #hyderabad #jharkhand #Odisha #OdishaNews

#airblowersinchennai#industrial air blower#manufactring company#sludgedewatring#vacuum pumps#airblower#delhi#sewage treatment plant manufacturer#waste water#a1blowers

2 notes

·

View notes

Text

#all pump series manufacturer india#pump series supplier india#pump series exporter india#comprehensive pump manufacturer india#all types of pumps supplier india#pump series export india#industrial pump manufacturer india#multi-series pump supplier india#pump solutions exporter india#india pump series manufacturer#bulk pump series supplier india#pump manufacturer and exporter india#all pump types supplier india#india pump series export company

0 notes

Text

The Ocean Sciences Building at the University of Washington in Seattle is a brightly modern, four-story structure, with large glass windows reflecting the bay across the street.

On the afternoon of July 7, 2016, it was being slowly locked down.

Red lights began flashing at the entrances as students and faculty filed out under overcast skies. Eventually, just a handful of people remained inside, preparing to unleash one of the most destructive forces in the natural world: the crushing weight of about 2½ miles of ocean water.

In the building’s high-pressure testing facility, a black, pill-shaped capsule hung from a hoist on the ceiling. About 3 feet long, it was a scale model of a submersible called Cyclops 2, developed by a local startup called OceanGate. The company’s CEO, Stockton Rush, had cofounded the company in 2009 as a sort of submarine charter service, anticipating a growing need for commercial and research trips to the ocean floor. At first, Rush acquired older, steel-hulled subs for expeditions, but in 2013 OceanGate had begun designing what the company called “a revolutionary new manned submersible.” Among the sub’s innovations were its lightweight hull, which was built from carbon fiber and could accommodate more passengers than the spherical cabins traditionally used in deep-sea diving. By 2016, Rush’s dream was to take paying customers down to the most famous shipwreck of them all: the Titanic, 3,800 meters below the surface of the Atlantic Ocean.

Engineers carefully lowered the Cyclops 2 model into the testing tank nose-first, like a bomb being loaded into a silo, and then screwed on the tank’s 3,600-pound lid. Then they began pumping in water, increasing the pressure to mimic a submersible’s dive. If you’re hanging out at sea level, the weight of the atmosphere above you exerts 14.7 pounds per square inch (psi). The deeper you go, the stronger that pressure; at the Titanic’s depth, the pressure is about 6,500 psi. Soon, the pressure gauge on UW’s test tank read 1,000 psi, and it kept ticking up—2,000 psi, 5,000 psi. At about the 73-minute mark, as the pressure in the tank reached 6,500 psi, there was a sudden roar and the tank shuddered violently.

“I felt it in my body,” an OceanGate employee wrote in an email later that night. “The building rocked, and my ears rang for a long time.”

“Scared the shit out of everyone,” he added.

The model had imploded thousands of meters short of the safety margin OceanGate had designed for.

In the high-stakes, high-cost world of crewed submersibles, most engineering teams would have gone back to the drawing board, or at least ordered more models to test. Rush’s company didn’t do either of those things. Instead, within months, OceanGate began building a full-scale Cyclops 2 based on the imploded model. This submersible design, later renamed Titan, eventually made it down to the Titanic in 2021. It even returned to the site for expeditions the next two years. But nearly one year ago, on June 18, 2023, Titan dove to the infamous wreck and imploded, instantly killing all five people onboard, including Rush himself.

The disaster captivated and horrified the world. Deep-sea experts criticized OceanGate’s choices, from Titan’s carbon-fiber construction to Rush’s public disdain for industry regulations, which he believed stifled innovation. Organizations that had worked with OceanGate, including the University of Washington as well as the Boeing Company, released statements denying that they contributed to Titan.

A trove of tens of thousands of internal OceanGate emails, documents, and photographs provided exclusively to WIRED by anonymous sources sheds new light on Titan’s development, from its initial design and manufacture through its first deep-sea operations. The documents, validated by interviews with two third-party suppliers and several former OceanGate employees with intimate knowledge of Titan, reveal never-before-reported details about the design and testing of the submersible. They show that Boeing and the University of Washington were both involved in the early stages of OceanGate’s carbon-fiber sub project, although their work did not make it into the final Titan design. The trove also reveals a company culture in which employees who questioned their bosses’ high-speed approach and decisions were dismissed as overly cautious or even fired. (The former employees who spoke to WIRED have asked not to be named for fear of being sued by the families of those who died aboard the vessel.) Most of all, the documents show how Rush, blinkered by his own ambition to be the Elon Musk of the deep seas, repeatedly overstated OceanGate’s progress and, on at least one occasion, outright lied about significant problems with Titan’s hull, which has not been previously reported.

A representative for OceanGate, which ceased all operations last summer, declined to comment on WIRED’s findings.

5K notes

·

View notes

Text

EPC company in Pune Maharashtra

Welcome to Veda Engg, your trusted partner for comprehensive engineering solutions in Maharashtra. As a premier EPC (Engineering, Procurement, and Construction) company, we specialize in utility engineering, serving a diverse range of industries. Explore our expertise as an authorized Thermax dealer, steam boiler and thermic fluid heater supplier, hot water generator manufacturer, cooling tower specialist, and provider of steam accessories and systems, along with reliable operation and Manning services throughout Maharashtra.

EPC Company in Pune, Maharashtra:

Veda Engg stands as a leading EPC company in Pune, Maharashtra, offering end-to-end engineering solutions. Our expertise spans across diverse sectors, providing innovative and customized solutions to meet the unique requirements of our clients.

Utility Engineering Company in Maharashtra:

With a commitment to excellence, Veda Engg excels as a utility engineering company in Maharashtra. Our solutions are tailored to optimize utility systems, enhancing efficiency, sustainability, and overall operational performance for industries across the region.

Authorized Thermax Dealer in Maharashtra:

As an authorized Thermax dealer, Veda Engg brings you cutting-edge technologies and solutions from one of the industry leaders. Our partnership with Thermax ensures that you receive high-quality products and services, meeting the highest standards of performance and reliability.

Steam Boiler Supplier/Manufacturer in Maharashtra:

Veda Engg takes pride in being a trusted steam boiler supplier and manufacturer in Maharashtra. Our steam boilers are designed to deliver optimal performance, efficiency, and safety, making them the ideal choice for various industrial applications.

Thermic Fluid Heater Supplier/Manufacturer in Maharashtra:

Count on Veda Engg as your reliable thermic fluid heater supplier and manufacturer in Maharashtra. Our heaters are crafted with precision, ensuring the smooth operation of your industrial processes with efficient heat transfer capabilities.

Hot Water Generator Supplier/Manufacturer in Maharashtra:

Experience uninterrupted hot water supply with Veda Engg as your preferred hot water generator supplier and manufacturer in Maharashtra. Our generators are designed to meet the diverse hot water requirements of industries, ensuring reliability and energy efficiency.

Cooling Tower Supplier/Manufacturer in Pune, Maharashtra:

For top-tier cooling tower solutions in Pune, Maharashtra, turn to Veda Engg. Our cooling towers are engineered to deliver superior heat dissipation, optimizing the performance of your industrial processes.

Steam Accessories & System in Maharashtra:

Veda Engg offers a comprehensive range of steam accessories and systems in Maharashtra, enhancing the efficiency and reliability of your steam-based operations. Trust us for cutting-edge solutions that meet the highest industry standards.

Operation & Manning Services in Maharashtra:

Ensure seamless operations with Veda Engg's operation and Manning services in Maharashtra. Our experienced team is dedicated to providing reliable and efficient services to keep your systems running smoothly.

Conclusion:

Choose Veda Engg as your preferred engineering partner in Maharashtra. With our expertise as an EPC company, authorized Thermax dealer, and supplier/manufacturer of various industrial solutions, we are committed to delivering excellence in every aspect of your project. Elevate your engineering experience with Veda Engg - where innovation meets reliability.

9130099434

#EPC company in Pune Maharashtra#Industrial pump dealers/ supplier in Pune/ Mumbai#Cooling tower supplier/manufacturer in Gujarat#Utility engineering company in Maharashtra

0 notes

Link

Looking for the best water chiller for your home or business? Look no further! Our selection of top-rated water chillers is designed to provide reliable and efficient cooling for all your needs. From compact countertop models to powerful commercial units, we offer a range of sizes and features to suit any application. Our chillers are built to last, with durable components and easy-to-use controls. To know more information visit: https://www.eseminternational.com/

0 notes

Video

youtube

Boeing Is Everything Wrong With American Capitalism

Excuse my language, but why is Boeing such a shitty corporation?

Their planes are literally falling apart in the sky.

At least six Boeing planes have had parts fall off this year — including an exit door in mid-flight. A whistle-blower has accused Boeing of a “criminal cover-up” of its safety failures.

But beyond this one company, Boeing’s descent is a case study in how American capitalism has become so rotten. Let me explain.

I’m old enough to remember when people used to say “If it’s not Boeing, I’m not going.”

But in 1997, everything changed when Boeing merged with McDonnell Douglas and became the only major maker of commercial aircraft in America. With no domestic rivals, it no longer needed to stay on the cutting edge of innovation.

Executives at Boeing who once specialized in engineering were replaced with Wall Street types who looked down on the engineers. One money-hungry CEO described those who cared too much about the integrity of Boeing’s planes, and not enough about its stock price, as “phenomenally talented assholes.”

To keep Wall Street happy, Boeing began spending billions on stock buybacks that pumped up the value of shares — money that could have been spent on safety and innovation.

It doled out hundreds of millions on campaign contributions and lobbying to lower safety standards, rake in massive government contracts, and boost its bottom line.

To cut costs, Boeing outsourced roughly 70% of its design, engineering, and manufacturing rather than rely on its experienced union workforce.

To further undercut its union, Boeing opened an assembly plant in South Carolina, a notorious anti-union state. Executives reportedly told managers not to move any unionized employees there.

This quest for profit resulted in massive quality control problems that were reported by engineers and machinists, but allegedly ignored by management. All of this inevitably led to the deadly safety issues Boeing faces today.

And because of Boeing’s monopoly-like power, it has been largely immune from any repercussions for its poor performance.

Boeing made it seem like it was punishing executives who led it astray by firing them, but still rewarded them with “golden parachutes” on the way out.

Folks, Boeing’s troubles should serve as a cautionary tale. It’s reflective of broader trends in our economy over the past forty years. Monopolization. Wealth siphoned off to rich shareholders at the expense of everyone else. Cutting corners on safety to save a dime. Bashing unions. All while spending big money lobbying the government.

Boeing may have become a shitty company, but that doesn’t mean we have to put up with it.

The government has the power to increase antitrust enforcement to bust up big companies — something that we are already starting to see in other industries.

It should also attach strings to government contracts and subsidies to ensure that private corporations are working in the best interest of the country, and not just their bottom lines.

It should ban stock buybacks, which were illegal before the Reagan administration, so profits are put back into improving the company, including the safety of products, rather than solely padding investors’ wallets.

Union power should be rebuilt, so that workers can once again act as a countervailing force to Wall Street.

And we should continue the fight to get Big Money out of politics.

It’s not too late to reverse course and chart a new flight path.

500 notes

·

View notes

Text

I'm about to ask a question that I know none of you individually can answer entirely, it's more like I'm hoping the knowledge can be condensed out of the ether by everyone collectively: why can't I just go to startrek.com and buy a Starfleet uniform? Isn't this the one piece of clothing most Trek fans want to have? Why have we been essentially left to our own devices on this for decades?

There used to be a company called Rubie's that made pretty reasonable costume uniforms from TNG and DS9/VOY but they went out of business or stopped making them or something; I haven't seen one in geological eons

Anovos made insanely great-looking product but it cost a million dollars and shipped 🤷♂️???when???🤷♂️ Anyway they're out of business too

Sure, you can go to Amazon and find a reasonable-looking costume uniform for cheap from a place with a weird name you've never heard of in your life, but ……… odds are near 100% it comes from some kind of appalling exploitation factory of some sort, right? The irony of buying a Starfleet uniform made by slave labor, no thank you

Something like 10-15 years ago ThinkGeek sold a line of two-piece PJs that were surprisingly excellent versions of a TNG s03+ uniform, like someone over there was PAYING ATTENTION and doing really solid work

Anyway ThinkGeek is also out of business

But like: how the fuck? Is this not a solved problem? For the Star Trek Industrial Complex? I get that supply chains are complicated and all that, but if you can pump out kinda janky one-off merch for Star Trek Day, how hard is it to source a manufacturer for a Starfleet uniform replica that looks decent and doesn't cost a literal thousand dollars?

That's what I want: to be able to just get a uniform that looks okay (I don't need 100% SCREEN ACCURATE PERFECTION TO THE MICRODETAIL) and won't cost a down payment; is that not ……….. possible? Is there something about vending Starfleet uniforms that's economically impractical or somehow legally infeasible or something else that we just aren't aware of??* Who do I talk to about this???

* Like: did they do the math and discover that the majority of Trek fans inexplicably want those Santa suits from the Wrath of Khan era which are probably impossible to manufacture at scale for a decent price and just went fuck this

#star trek#questions for some executive somewhere#mr van citters turn on your location i just want to ask a question

367 notes

·

View notes

Text

Short of dot-com type of a bust, spending on AI data centers will continue to skyrocket, with attendant energy demand. Utility companies should be in panic mode to increase generating capacity, but they are not. The resulting squeeze will drive consumer prices through the roof and put exorbitant strain on the electric grid. But rest assured that AI companies will suffer no outages. ⁃ TN Editor

The rapid growth of data centers to support AI is significantly increasing global electricity demand.

This surge in demand threatens to outpace the development of renewable energy sources.

International regulations are needed to ensure tech companies use clean energy and minimize their impact on climate goals.

The global electricity demand is expected to grow exponentially in the coming decades, largely due to an increased demand from tech companies for new data centers to support the rollout of high-energy-consuming advanced technologies, such as artificial intelligence (AI). As governments worldwide introduce new climate policies and pump billions into alternative energy sources and clean tech, these efforts may be quashed by the increased electricity demand from data centers unless greater international regulatory action is taken to ensure that tech companies invest in clean energy sources and do not use fossil fuels for power.

The International Energy Agency (IEA) released a report in October entitled “What the data centre and AI boom could mean for the energy sector”. It showed that with investment in new data centers surging over the past two years, particularly in the U.S., the electricity demand is increasing rapidly – a trend that is set to continue.

The report states that in the U.S., annual investment in data center construction has doubled in the past two years alone. China and the European Union are also seeing investment in data centers increase rapidly. In 2023, the overall capital investment by tech leaders Google, Microsoft, and Amazon was greater than that of the U.S. oil and gas industry, at approximately 0.5 percent of the U.S. GDP.

The tech sector expects to deploy AI technologies more widely in the coming decades as the technology is improved and becomes more ingrained in everyday life. This is just one of several advanced technologies expected to contribute to the rise in demand for power worldwide in the coming decades.

Global aggregate electricity demand is set to increase by 6,750 terawatt-hours (TWh) by 2030, per the IEA’s Stated Policies Scenario. This is spurred by several factors including digitalization, economic growth, electric vehicles, air conditioners, and the rising importance of electricity-intensive manufacturing. In large economies such as the U.S., China, and the EU, data centers contribute around 2 to 4 percent of total electricity consumption at present. However, the sector has already surpassed 10 percent of electricity consumption in at least five U.S. states. Meanwhile, in Ireland, it contributes more than 20 percent of all electricity consumption.

10 notes

·

View notes

Text

This is my favorite old Aermotor wind pump in Lassen County, California, USA. It is in a field just a few miles south of the community of Madeline. It stands there proudly doing its job to keep the cattle watered day in and day out.

Madeline is an unincorporated community in Lassen County, California, USA, approximately 45 miles north of Susanville on US-395. This is a very remote and rural part of northern California. The predominate industries here are cattle ranching and hay farming but there has been some mining, including gold mining in the region over the years.

The Aermotor Windmill Company has been a strong competitor in the wind driven pump industry since the late 19th century. During World War II the company played a role in the manufacture of the then top secret Norden Bombsight which helped the allies win the war. Today the company is the premier manufacturer of wind driven pumps in America with approximately an 80% market share.

I captured this image on an October evening after the sun had dropped well below the horizon and some thick clouds moved in. I felt the textures in the scene lent themselves to black and white. Prints and merch: https://buff.ly/3uW2kR0

#original photographers#photographers on tumblr#northern california#original photographic works#original photography on tumblr#lassen county#fine art photography#blackandwithephotography#rural america#monochomatic#windmill#aermotor

28 notes

·

View notes

Text

Excerpt from this story from Canary Media:

The world’s biggest decarbonization challenge comes not from cars, planes, or power plants, but from the highly polluting heavy industries at the heart of modern society.

New data from the Rhodium Group shows that, worldwide, no sector emits more planet-warming carbon dioxide than industry. That fact is not projected to change in the decades to come.

Cement, steel, petrochemicals, and various other mass-produced industrial metals and materials, from aluminum to glass, are ubiquitous.

They also make up an enormous and rising share of the world’s carbon dioxide emissions.

In 2022, the industrial sector accounted for 31 percent of global greenhouse gas emissions. By 2050, Rhodium forecasts that the industrial sector could emit as much CO2 equivalent as the power, transportation, and building sectors combined.

The biggest driver of industrial emissions is oil and gas production. The manufacturing of cement and other non-metallic minerals is the next-biggest contributor, followed by steel and iron production.

Emissions from oil and gas production mostly stem from the enormous amount of “fugitive” methane that escapes into the atmosphere: 80 percent of the sector’s emissions take this form.

In cement production, there are two key sources of emissions: high-heat, gas-fired kilns and the limestone used as an ingredient in Portland cement, which releases CO2 when heated up. Steelmaking emissions mainly come from the use of coal-fired blast furnaces to make iron.

Many of these industrial sectors have historically been described as “hard-to-decarbonize,” but in recent years experts have pushed back on that label as new pathways to cleaning up heavy industry have emerged or been proven out.

Rhodium, for its part, sees the oil and gas industry’s fugitive methane problem as solvable thanks to “cost-effective mitigation solutions that exist today,” the report notes. Plus, if global fossil-fuel consumption falls due to the rise of clean energy, heat pumps, and EVs, those emissions will follow suit.

The report also sees a solid pathway for the steelmaking sector to become less carbon-intensive by increasing both the use of electric arc furnaces, which use electricity to recycle scrap steel, as well as an alternative, coal-free ironmaking process called direct reduction, which can be fueled by fossil gas or hydrogen.

The research firm is less optimistic about cement emissions in the near term, citing a lack of mature technologies. Major cement producers and startups are working on different techniques to chip away at emissions, and companies are also devising ways to produce low-carbon Portland cement, but the industry is still far from the wholesale transformation needed to radically reduce emissions.

7 notes

·

View notes

Text

A1 Air Blowers provide efficient solutions for a variety of industrial and commercial applications. They are designed to offer powerful airflow, ensuring the removal of dust, debris, and moisture from equipment or workspaces.

These blowers are highly energy-efficient, reducing operating costs while maintaining high performance. Built with durable materials, A1 Air Blowers are reliable and long-lasting, minimizing downtime and maintenance. Their compact design makes them easy to install and integrate into existing systems.

Ideal for cooling, ventilation, and air circulation, they contribute to a safer and cleaner work environment. With customizable options, A1 Air Blowers cater to specific needs across industries.

☎️ 𝗠𝗼𝗿𝗲 𝗜𝗻𝗳𝗼𝗿𝗺𝗮𝘁𝗶𝗼𝗻

📱 +91 9953088849, +91 062043 85227

🌐 www.a1blowers.com

#AirBlower #sewagetreatmentplant #sewagetreatment #sewagepump #effluenttreatment #EFFLUENTTREATMENTPLANT #wastewater #wastewatertreatment #wastewatertreatmentplant #wastewatermanagement #effluent #aircompressor #aircompressorparts #compressor #aircompressorservice #india #noidacity #delhi #delhifood #DelhiNews #pune #PuneNews #bengaluru #ahmedabad #ahmedabad_instagram #gujarat #gujarati #mumbai #industrial #industry #industrialequipment #industrialdesign #madhyapradesh #MadhyaPradeshNews #like #jharkhand #punjabi #punjabistatus #ghaziabad #UttarPradesh #uttarakhand #haryana

#airblowersinchennai#industrial air blower#manufactring company#sludgedewatring#vacuum pumps#airblower#delhi#sewage treatment plant manufacturer#waste water#a1blowers

2 notes

·

View notes

Text

The Role of Pour Point Depressants in the Oil and Gas Industry

The oil and gas industry relies heavily on chemical additives to optimize production and ensure the smooth flow of crude oil and its derivatives. One such crucial additive is the Pour Point Depressant (PPD), a chemical that significantly impacts the handling and transportation of oil, especially in cold climates. Pour point depressants play a vital role in preventing wax formation and lowering the pour point of crude oil, ensuring that the oil remains fluid even at low temperatures. In this blog, we will explore the importance of PPDs in the oil and gas industry, their function, and why sourcing them from a reliable pour point depressant manufacturer in India is critical for oilfield operations.

Understanding Pour Point and Its Importance

The pour point of a liquid is the lowest temperature at which it remains fluid and pourable. For crude oil and its derivatives, this is a critical property, especially when transporting and storing oil in cold environments. At low temperatures, the waxy components in crude oil begin to crystallize, leading to an increase in viscosity and eventually causing the oil to solidify. This solidification can clog pipelines, damage equipment, and halt oil production altogether.

The introduction of pour point depressants (PPDs) solves this problem. These chemical additives prevent the crystallization of wax in the oil, keeping it fluid and reducing its pour point. By modifying the wax crystals' size and shape, PPDs ensure that the oil remains pumpable even at low temperatures, making them indispensable in the global oil industry.

How Pour Point Depressants Work

Pour point depressants work by interacting with the wax molecules in crude oil, modifying their structure to prevent them from forming large crystals that could impede the flow of oil. The depressants either inhibit the formation of wax crystals or reduce their size, allowing them to stay suspended in the oil without agglomerating. This process helps maintain the oil's viscosity, ensuring it remains flowable at lower temperatures.

In essence, PPDs modify the temperature at which wax crystallization occurs, reducing the likelihood of solidification and blockages. This allows for smoother transportation and processing of oil, particularly in cold weather conditions where oil solidification is a significant concern.

The Benefits of Pour Point Depressants

The use of pour point depressants offers several key benefits to the oil and gas industry. These benefits range from operational efficiency to cost savings, making them an integral part of modern oilfield operations.

1. Ensures Continuous Flow of Oil

The primary advantage of using PPDs is that they ensure the continuous flow of oil through pipelines and storage facilities. By lowering the pour point, PPDs allow oil to remain in a liquid state even in freezing temperatures, preventing blockages and ensuring smooth operations.

2. Reduces Energy Costs

In the absence of PPDs, heating systems are often used to keep oil above its pour point, especially during transportation. This can be energy-intensive and costly. By using pour point depressants, companies can significantly reduce the need for heating, cutting down on energy consumption and lowering operational costs.

3. Prevents Equipment Damage

Solidified oil can cause significant wear and tear on pipelines, pumps, and other oilfield equipment. This leads to expensive repairs and potential downtime. PPDs prevent solidification, reducing the risk of equipment damage and enhancing the longevity of oilfield infrastructure.

4. Improves Storage Efficiency

Storing crude oil in colder climates can be challenging due to the risk of solidification. By incorporating PPDs, storage becomes more efficient as the oil can remain fluid and pumpable, even during extended periods of storage in cold conditions.

5. Facilitates Safe Transportation

The safe transportation of crude oil is a top priority for oil companies. PPDs play a crucial role in ensuring that oil remains fluid during long journeys, particularly when traversing colder regions. By preventing blockages in pipelines and tankers, pour point depressants contribute to safer and more efficient oil transportation.

The Role of Pour Point Depressants in India's Oil and Gas Sector

India, as a major player in the global oil and gas industry, has seen a growing demand for advanced oilfield chemicals to enhance efficiency and safety in oil production and transportation. With its diverse climate and geographical challenges, including cold regions in the north, India requires high-performance pour point depressants to ensure that its oil production and transportation networks remain operational.

Leading PPD Manufacturers in India

India is home to several prominent pour point depressant manufacturers, with a strong presence in key industrial hubs like Gujarat. As a top pour point depressant manufacturer in India, Imperial Oilfield Chemicals Pvt. Ltd. is committed to providing high-quality PPD solutions that meet the stringent requirements of the oil and gas industry.

Being located in Gujarat, particularly in Vadodara, offers numerous advantages for PPD manufacturing. Vadodara is a significant industrial center with excellent access to raw materials, infrastructure, and skilled labor, making it an ideal base for oilfield chemical production. Imperial Oilfield Chemicals Pvt. Ltd., a leading pour point depressant manufacturer in Vadodara, is well-positioned to meet the needs of oil companies both within India and abroad.

Exporting PPDs to Global Markets

India's oilfield chemicals sector is not just focused on domestic demand but is also an important player in the global market. As a pour point depressant exporter in India, Imperial Oilfield Chemicals Pvt. Ltd. has established a strong presence in international markets, supplying high-performance PPDs to countries across the globe. Our PPDs meet international quality standards and are trusted by oil companies for their effectiveness in extreme weather conditions.

Choosing the Right Pour Point Depressant

Selecting the right pour point depressant for specific oilfield operations is critical. The choice of PPD depends on several factors, including the type of crude oil, operating temperatures, and the specific challenges faced by the oilfield. High-quality PPDs are designed to work across a broad range of crude oils, ensuring flexibility and effectiveness in diverse environments.

At Imperial Oilfield Chemicals Pvt. Ltd., we offer a range of pour point depressants tailored to meet the unique needs of our clients. As a pour point depressant manufacturer in Gujarat, we understand the challenges faced by oil companies operating in varying climates and environments, and our products are designed to provide reliable performance across the board.

The Future of Pour Point Depressants in India

The demand for pour point depressants is expected to grow in India, driven by the expansion of the oil and gas sector and the need for more efficient, cost-effective oil production and transportation methods. As one of the best oilfield chemicals companies in India, Imperial Oilfield Chemicals Pvt. Ltd. is at the forefront of this growth, continuously innovating and improving our products to meet the evolving needs of the industry.

Why Choose Imperial Oilfield Chemicals Pvt. Ltd.?

At Imperial Oilfield Chemicals Pvt. Ltd., we are committed to providing our clients with high-quality pour point depressants that enhance the performance and safety of their oilfield operations. Here are a few reasons why we are considered the best oilfield chemicals company in India:

1. Expertise in Oilfield Chemicals

With years of experience in manufacturing oilfield chemicals, including PPDs, we have developed a deep understanding of the challenges faced by the oil and gas industry. Our expertise allows us to offer innovative solutions that meet the specific needs of our clients.

2. Quality Assurance

We adhere to strict quality control measures at every stage of production to ensure that our PPDs meet the highest standards of performance and reliability. Our commitment to quality has made us a trusted pour point depressant manufacturer in Vadodara and beyond.

3. Global Reach

As a leading pour point depressant exporter in India, we serve clients not only within India but also across the globe. Our ability to meet international standards and deliver high-performance PPDs has earned us a reputation as a reliable partner in the oil and gas industry.

4. Customer-Centric Approach

We understand that every oilfield operation is unique, which is why we work closely with our clients to develop customized PPD solutions that meet their specific requirements. Our customer-centric approach has helped us build long-lasting relationships with oil companies both in India and internationally.

Conclusion

Pour point depressants play a crucial role in ensuring the smooth flow of oil, particularly in cold environments where wax formation can hinder production and transportation. As a trusted pour point depressant manufacturer in India, Imperial Oilfield Chemicals Pvt. Ltd. is proud to offer high-performance PPDs that help oil companies optimize their operations and reduce costs.

Our commitment to quality, innovation, and customer satisfaction has made us one of the leading pour point depressant manufacturers in Gujarat and a key pour point depressant exporter in India. If you are looking for reliable, high-quality PPDs to enhance your oilfield operations, look no further than Imperial Oilfield Chemicals Pvt. Ltd.

#Best oilfield chemicals company in India#Pour point depressant exporter in India#Pour point depressant manufacturer in Vadodara#Pour point depressant manufacturer in Gujarat#Pour point depressant (PPD)#Pour point depressant manufacturer in India#India#Africa#Kuwait#Bahrain#United Arab emirates#Jordan

4 notes

·

View notes

Text

The Science behind RO Technology in Delhi: How Netsol Water Ensures Purity

Netsol Water is a leading Commercial RO Plant Manufacturer in Delhi, providing advance solutions for waste water management. Reverse Osmosis is an advanced purification technology used to eliminate contaminants from water sources. This entails pumping water through a porous membrane where the impurities are retained while the water is collected on the other side. It is very essential method to get safe water to drink because sometimes the water quality can be a big issue in places such as Delhi.

This approach applies hydraulic pressure to filter water through a semi-permeable membrane that retains dissolved solids. It is one of the most efficient methods of getting water free from impurities because it can target most salinity particles, bacteria, and other microorganisms. RO technology is based on the phenomenon of osmosis, which is a natural process of water diffusion from an area of low solute concentration to an area of high solute concentration.

Different kinds of RO systems by Netsol water in Delhi

Netsol Water is one of the best Commercial RO Plant Manufacturer in Delhi, offering cutting-edge solutions for waste water. Netsol Water is a well-known Water purification company, which deals in a number of RO systems, which satisfy the consumer’s need and demand. Their techniques involve the application of modern technology to produce very effective water purification.

Some of the RO systems offered by Netsol Water in Delhi include:

1. Domestic RO systems: Most of them are household systems since they serve the purpose of supplying clean and safe water for drinking to the family. These RO systems come in various sizes thus they fit all households perfectly.

2. Commercial RO systems: For business organizations that need large volumes of purified water, Netsol Water provides commercial reverse osmosis systems. These systems are appropriate for the restaurant, hotel, and any commercial building requiring huge volumes of water in a single day.

3. Industrial RO systems: For industries that require water with certain quality, Netsol Water offers its industrial RO systems. They are able to accommodate large quantities of water and are made to serve several operations of different sectors.

How Netsol Water Ensure Purity by Their Reverse Osmosis Technology in Delhi?

Netsol Water is a trusted Commercial RO Plant Manufacturers in Delhi, offering solutions for waste water. Netsol Water takes several steps to ensure purity in its RO systems in Delhi:

1. Pre-filters: In the process of water filtration to the RO membrane, there is a pre-filter which filters out big particles like sand, dust as well as sediment. This keeps the membrane in check to avoid damage while at the same time guaranteeing an efficient process of filtration.

2. Activated carbon filters: These filters eliminate chlorine, organic substances, and other chemical agents to provide water that does not have an unpleasant taste or smell. This process also serves to optimize the same RO membrane itself.

3. Reverse osmosis: The RO membrane is the most central part of the purification process in the entire system. Thus when water is passed through this membrane all forms of impurities are left behind thus collecting pure water only.

4. Post-filters: Following filtration through the RO membrane, the purified water is filtered again through a post-filter that enhances the taste and appearance of the water.

5. Storage tank: Last but not the least; purified water is stored in a tank for use. This storage tank ensure that the water remains clean and free from other contaminate that may find their way into the water.

Conclusion

Netsol Water is top on Commercial RO Plant Manufacturer in Delhi, providing waste water solutions. Reverse Osmosis technology makes it possible to provide clean and safe drinking water, which is very important in a city such as Delhi where water quality is questionable at times. The latest technologies are incorporated in Netsol Water’s superior RO systems to deliver thoroughly purified water for residential, commercial and industrial uses. Thus through pre-filters, activated carbon filters as well as post-filters, Netsol Water’s RO Systems guarantee that impurities and contaminants have been eliminated to make water clean, pure and healthy for all to drink.

#environment#manufacturer#industries#water#environmental#manufacturers#industrial#netsolwater#purifier#manufacturing#industry#wastewater#filter#business#management#delhi

2 notes

·

View notes

Text

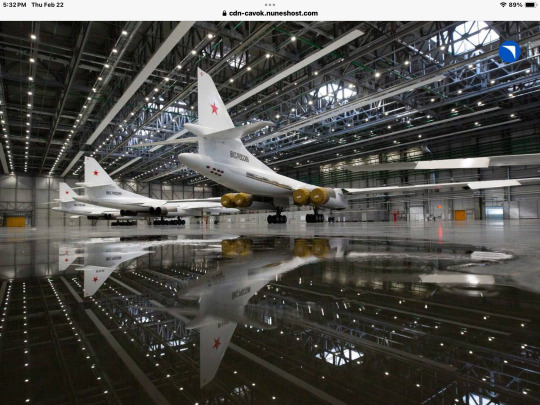

IMAGES: Russia resumes production of modernized Tu-160 bombers

Russia plans to eventually buy 50 new Tu-160M and modernize 15 existing Tu-160.

Fernando Valduga By Fernando Valduga 02/22/2024 - 08:17 in Military

Russia restarted the production of the Tupolev-160 strategic bombers, known as Blackjack, with the announcement coming from Sergey Chemezov, CEO of the state company Rostec.

"Restarting the production of the Tu-160 was quite a task for all Rostec affiliates. The project documentation was fully digitized within the tightest deadlines. The vacuum welding technique of titanium parts was restored and the production of fuselage units was resumed. Today we can safely say that we have been successful in all aspects," he said, according to the Russian state media.

The updated Tu-160M maintains the exterior design of its predecessor, but incorporates a technological base and completely new digital solutions.

The recent visit of Russian President Vladimir Putin to the S.P. aviation factory. Gorbunov Kazan, in Tartaristan, where he inspected four updated strategic bombers, drew attention amid concerns about the country's military capabilities.

The Tu-160, recognized as the largest and most powerful supersonic aircraft with wings of variable geometry in the history of military aviation, underwent an update program initiated by Putin's decision.

The government contract, signed between the Ministry of Industry and Commerce and the Tupolev design department, facilitated the digitization of the Tu-160M aircraft design documentation and the restoration of vacuum welding techniques for titanium products, leading to the resumption of the production of fuselage units.

Rostec's main industrial companies in metallurgy, aircraft design, engineering and instrument manufacturing have played crucial roles in revitalizing their cooperation for the successful resumption of production.

The first Tu-160M strategic bomber built from scratch made its first 30-minute flight on January 12, 2022. It is equipped with modern weapons, electronic warfare system, as well as on-board electronic equipment.

According to reports, the Tu-160 entered Soviet service for the first time in the late 1980s, with production until 1995. In 2015, Russian President Vladimir Putin ordered the resumption of production of the updated variant of the Tu-160M to strengthen the strategy of the Russian Air Force in the capabilities of the bombers at a time of increasing tension with the West, and to compensate for delays in the future PAK-DA bomber program.

Russia plans to eventually buy about 50 Tu-160M bombers and is upgrading 16 existing Tu-160s to the modernized standard. With the first Tu-160M scheduled to be delivered soon, series production is expected to begin in 2023, at a production rate of at least three aircraft per year. This would fit the order for 10 aircraft in the period 2023–27.

The update of the Tu-160M is being implemented in two phases, with the first phase of the Tu-160M1 comprising the new navigation system K-042K-1 and autopilot ABSU-200-1, as well as the removal of some previous systems, such as pump observation systems. This variant of the Tu-160M1 has been operational in the Russian Air Force since the end of 2014.

The second phase of the Tu-160M2 includes the new Novella NV1.70 radar, a digital glass booth, modern communications and anti-jamming equipment, updated NK-32 engines (designated NK-32-02) and modern conventional and nuclear weapons.

Tags: Military AviationROSTECRussiaTu-160 Blackjack

Sharing

tweet

Fernando Valduga

Fernando Valduga

Aviation photographer and pilot since 1992, he has participated in several events and air operations, such as Cruzex, AirVenture, Dayton Airshow and FIDAE. He has works published in specialized aviation magazines in Brazil and abroad. He uses Canon equipment during his photographic work in the world of aviation.

Related news

MILITARY

US released the F-16 to Ankara and F-35 to Athens, but with some conditions

21/02/2024 - 23:09

MILITARY

B-52 flies with Filipino fighters over the South China Sea

21/02/2024 - 22:24

MILITARY

Norway receives first C-130J-30 Super Hercules with Block 8.1 update

21/02/2024 - 21:56

MILITARY

Greece and France block supply of Turkish UAVs to Ukraine

21/02/2024 - 17:00

HELICOPTERS

Indra will develop H225M helicopter simulator for the Singapore Republic Air Force

21/02/2024 - 16:00

HELICOPTERS

Schiebel wins contract with Camcopter S-300 for the South Korean Navy

21/02/2024 - 14:00

11 notes

·

View notes

Text

GI Flanges Manufacture

Galvanized Iron (GI) flanges are essential components used in a variety of industrial applications, particularly in piping systems. They connect pipes, valves, pumps, and other equipment, ensuring a secure and efficient transfer of fluids or gases. Industries like water treatment, oil and gas, power plants, and chemical processing frequently rely on GI flanges due to their durability and resistance to corrosion.

What Are GI Flanges?

GI flanges are manufactured from galvanized iron, which is coated with zinc to prevent corrosion. This protective layer enhances their lifespan and makes them ideal for use in environments exposed to moisture, chemicals, and harsh conditions.

The main functions of GI flanges include:

Pipe Connection: They help form strong joints between pipes.

Maintenance Access: Flanges allow easy disassembly for cleaning, inspection, or repairs.

Valve Support: They secure valves in place within the piping system.

The GI Flange Manufacturing Process

Material Selection: High-quality iron or steel is selected for the manufacturing process.

Forging: The raw material is heated and shaped into a flange.

Galvanization: The flange is dipped in molten zinc to form a protective layer.

Machining: Final dimensions are achieved through precise machining processes.

Quality Inspection: A thorough inspection ensures that the flange meets the required standards.

Types of GI Flanges

Weld Neck Flanges: Designed for high-pressure systems, these flanges are welded to pipes, providing a strong connection.

Slip-On Flanges: These are slid over the pipe and then welded, commonly used in low-pressure applications.

Blind Flanges: Used to close the ends of pipes, they help isolate sections of a pipeline.

Socket Weld Flanges: Ideal for small-diameter pipes, they offer a smooth bore for better fluid flow.

Advantages of Using GI Flanges

Corrosion Resistance: The zinc coating protects the flange from rust, especially in environments with high moisture or chemical exposure.

Durability: GI flanges are known for their strength and long service life.

Cost-Effective: The extended lifespan of GI flanges reduces the need for replacements, saving costs in the long run.

Versatility: These flanges can be used in various industrial applications, from plumbing to firefighting systems.

Udhhyog: Leading GI Flanges Manufacturer

Udhhyog is a trusted manufacturer of high-quality flanges, including GI flanges, designed to meet the needs of different industries. The company ensures strict quality controls and precision manufacturing to deliver durable, efficient products for various piping systems.

For further information on Udhhyog’s GI flange products, visit their website or get in touch through their social media platforms.

#GIFlanges#FlangeManufacture#PipingSystems#GalvanizedIron#IndustrialFlanges#PipeConnection#CorrosionResistance#Udhhyog#IndustrialSolutions#ValveSupport#DurableFlanges#PipeFittings#EngineeringSolutions#IndustrialManufacturing

2 notes

·

View notes

Text

GI Flanges at the Lowest Price in Maharashtra

Maharashtra, one of India's leading industrial states, is renowned for its diverse manufacturing sector, ranging from textiles to heavy machinery. For businesses in this vibrant market, ensuring the procurement of high-quality industrial components is essential. Among these components, Galvanized Iron (GI) flanges play a crucial role in ensuring the durability and reliability of piping systems. At Udhhyog, we offer GI flanges at the lowest prices in Maharashtra, providing an excellent solution for all industrial applications.

GI flanges are essential for connecting pipes, valves, pumps, and other equipment in various industries, including construction, oil and gas, and water treatment. The unique properties of galvanized iron, such as resistance to corrosion and increased strength, make these flanges a preferred choice for many businesses. By opting for GI flanges, companies can significantly enhance the longevity and performance of their systems.

At Udhhyog, we prioritize quality without compromising on affordability. We understand the challenges faced by micro, small, and medium enterprises (MSMEs) in Maharashtra when it comes to procurement. Our technology-driven platform simplifies the purchasing process, ensuring that businesses can access top-notch GI flanges without breaking the bank. We source our products from trusted manufacturers, ensuring that our customers receive only the best quality.

One of the key advantages of purchasing GI flanges from Udhhyog is our competitive pricing. We strive to offer the lowest prices in the market, enabling our customers to optimize their budgets while still acquiring high-quality materials. Additionally, our streamlined supply chain ensures fast and efficient delivery, so you can keep your projects on schedule.

Moreover, Udhhyog provides flexible credit options tailored for MSMEs, empowering businesses to make purchases without immediate financial strain. This approach not only supports the growth of small businesses but also fosters a collaborative industrial ecosystem in Maharashtra.

In conclusion, if you're searching for GI flanges at the lowest price in Maharashtra, look no further than Udhhyog. Our commitment to quality, affordability, and customer satisfaction makes us the ideal partner for all your industrial needs. Explore our platform today and discover how we can help your business thrive in the competitive landscape of Maharashtra's industries.

#GFlanges#MaharashtraIndustry#IndustrialSupplies#AffordableQuality#MSMEs#Procurement#ConstructionMaterials#GalvanizedIron#Manufacturing#Udhhyog#SupplyChain#PipingSolutions#CorrosionResistant#QualityAssured#BusinessGrowth#Industry4.0#IndustrialProducts#MaharashtraManufacturers#CostEffective#TrustedSuppliers

2 notes

·

View notes